Home » Posts tagged '3d printing'

Tag Archives: 3d printing

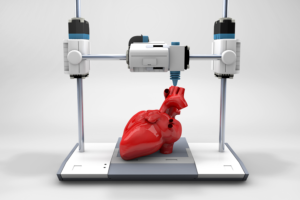

The Benefits and Risks of 3d Printing

3d Printing is a broad category of manufacturing processes that build parts layer-by-layer. It can be used in the entire product development cycle to accelerate prototype development and reduce design risk.

The process starts with CAD software that creates the digital model for the part. The resulting file is then sliced into horizontal cross-sections by the printer’s software. Contact By3Design now!

There are a number of factors that can affect the cost of 3D printing. First, the design of the product can increase the print’s complexity and drive up the need for support structures. This can add significant costs. In addition, the materials used to produce a part can also be expensive. The type of printer used can also play a role, as different types offer different levels of precision and detail.

Another factor is the time it takes to print a 3D object. The longer the build time, the higher the price per unit. In addition, the cost of energy used by the machine can increase the total cost. Fortunately, there are ways to reduce the overall cost of 3D printing. For example, printing multiple parts at once can reduce the cost per piece and save on initial investment. Bulk printing can also help reduce the cost of materials and minimize energy consumption.

In addition, the use of a 3D printer can significantly reduce warehousing and shipping costs. Additionally, the technology can be used to produce a prototype before investing in a new machine or design. This can reduce the time to market for a new product and help companies to avoid costly mistakes.

Moreover, 3D printing can eliminate the need for expensive tooling and reduce labour costs. Traditional manufacturing processes require several redesign cycles to produce a final product, which can cost a lot of money and lead to a high level of uncertainty. With the 3D printing technology, companies can produce a new prototype in a short amount of time, allowing them to make changes before production begins. This can improve the quality of the final product and lower production costs.

The cost of 3D printing depends on the type of material and the complexity of the model. For example, complex designs often require supports and may need more post-processing to remove them. It is important to consider these additional costs when planning a project. In addition, the price of the printer can vary considerably depending on its build volume and features.

Durability

The durability of 3d printing depends on the type of material used, the techniques employed, and the build environment. It is also important to consider the amount of post-processing required. Some printing technologies require significant sanding, etching, or curing time, which can increase the cost and complexity of a part. Other factors that affect the strength of a print include its infill density and pattern, which determine how much material is placed between walls. Orienting the part to distribute stress evenly can also improve its strength. Finally, the thickness of the walls can impact its strength and stiffness.

3D printing is the layer-by-layer fabrication of three-dimensional physical models from a digital model, often through the use of polymers and metals. It is a modern technology that has revolutionized the way products are made, from consumer goods to medical equipment. In addition, it has expanded the possibilities of manufacturing processes by allowing for more complex and customizable designs.

There are many different types of 3D printing methods, each with its own advantages and limitations. The right technology for an application will depend on the needs of the user and their budget. In addition to the upfront cost of the printer, users should factor in ongoing maintenance and materials costs. Some 3D printers require frequent calibration and maintenance, while others are easier to use and have automated features that reduce user interaction.

In addition to its ability to produce durable parts, 3D printing can save time and money by reducing the design cycle. The process allows for iterative design changes, which can result in better products. This enables companies to test products and services before investing in large-scale production.

While the initial popularity of 3D printing centered on polymer-based technologies, it has since been extended to use various metals and ceramics. However, it is a relatively new technology, and its durability is still an issue. For example, polymers tend to be weaker than steel, and the strength of a printed object is determined by its mechanical properties. These are defined by a number of criteria, including tensile strength and impact resistance.

Customisation

The emergence of 3D printing technology has transformed the way products are made, enabling manufacturers to customize their offerings. The ability to print custom components reduces manufacturing costs and speeds up delivery times, making it a valuable tool for businesses looking to improve customer satisfaction.

3D printing is an ideal method for producing bespoke items, such as fashion accessories. Designers can use this technology to assert their creative individuality, while consumers can purchase customised products that reflect their unique tastes and preferences. This approach to personalization is a growing trend in the fashion industry, with designers and consumers alike embracing the idea of self-expression through their clothing choices.

The process of creating a 3D printed product begins with the creation of a virtual design. This is done using computer-aided design (CAD) software, which allows for precise drawings and technical illustrations to be created. Once the virtual model is finished, it must be prepared for printing. This involves slicing it into hundreds or even thousands of thin, horizontal layers. The layering process is crucial, as it determines how much detail is visible on the final product.

Moreover, it enables users to choose from a range of materials and colours. This offers greater design freedom and allows for the creation of complex geometries, including internal lattices and organic shapes. This, in turn, can result in increased performance and reduced material usage, resulting in lower costs for manufacturers.

While traditional manufacturing methods can produce customised products, they are limited by their ability to handle changeovers in production. Injection moulding, for example, requires a new mould to be produced for each customised product, which can lead to high changeover costs and lengthy production timelines.

In contrast, 3D printing allows manufacturers to produce a single customized component at a time, which significantly reduces development and production costs. The ability to make a single part quickly and inexpensively also reduces inventory costs, allowing companies to keep up with demand without increasing stock levels. This process is particularly beneficial for e-commerce companies, who can offer customers a wide variety of customizable options.

Safety

Like any technology, 3D printing comes with a few safety risks. These risks include fire hazards, toxic fumes, and the presence of hazardous chemicals in the print. It is important to take steps to minimize these risks and ensure a safe working environment. This includes using proper personal protective equipment (PPE) and maintaining an appropriate working area for the printer. PPE should include eye protection, a dust mask, and respiratory protection. It is also important to use a ventilation system that is properly sized for the space and ideally equipped with a snorkel fume hood.

Fire Hazards

Many 3D printers reach high temperatures during operation, posing a fire hazard when they are not operated correctly. Problems such as thermal runaway, where the heating elements continue to heat at one point, can result in a fire that is difficult to extinguish. Additionally, combustible plastics can pose a fire hazard when they are exposed to heat.

To reduce these fire hazards, make sure that workers are not spending too much time in proximity to the operational printer. To do this, it may be helpful to install alternative cameras or other mechanisms to monitor the printer without employees being present in person. Employees should also be properly trained on the operating procedures for the 3D printer and the materials they are using. This training should cover everything from the basic operations of the machine to the handling of the materials and any special precautions that might be necessary for a particular material due to its toxicity or reactivity.

Fumes and Other Air Emissions

The printing process can produce a variety of harmful chemical vapors and ultrafine particles that can be dangerous to health. These gases and particles can cause respiratory irritation and may even contribute to a range of diseases and conditions, including cardiovascular disease and cancer. These gases can also contaminate indoor air and pose environmental risks. To minimize these hazards, it is important to use a 3D printer that uses low-emitting materials.

In addition to ensuring proper printing procedures, employees should also wear appropriate PPE when working around the 3D printer. This should include safety glasses or goggles to protect the eyes from small particulate matter and possible chemical splashes. It is also a good idea to use a vacuum with a HEPA filter to capture any fine particulates and chemicals in the air. It is also important to properly dispose of any used materials and avoid dry sweeping, as this can reintroduce the chemicals into the air. Finally, it is important to keep a fire extinguisher in the area where 3D printing is conducted. This should be a standard carbon dioxide or dry chemical extinguisher, depending on the type of material used for printing.